GHF Flat Pack 2

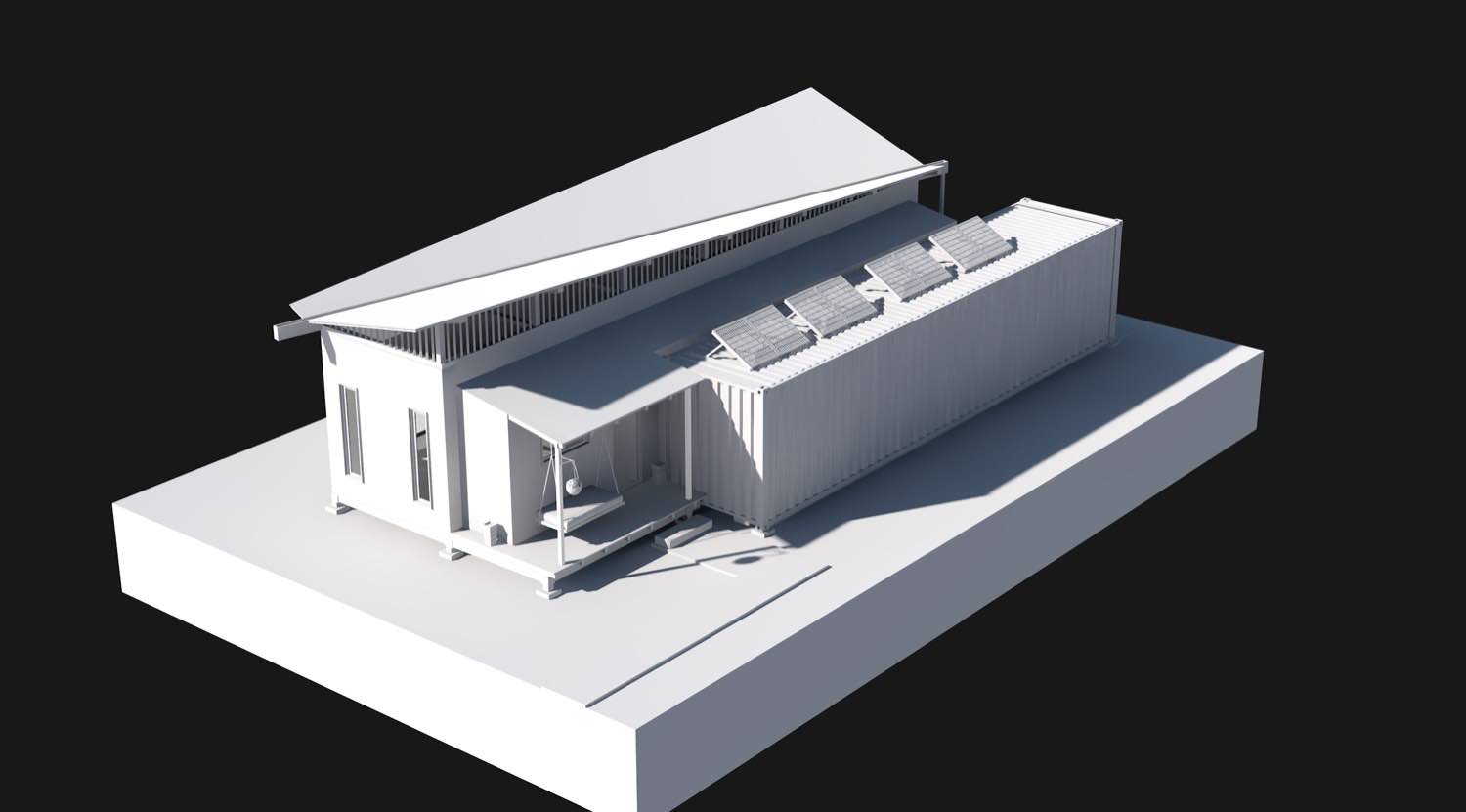

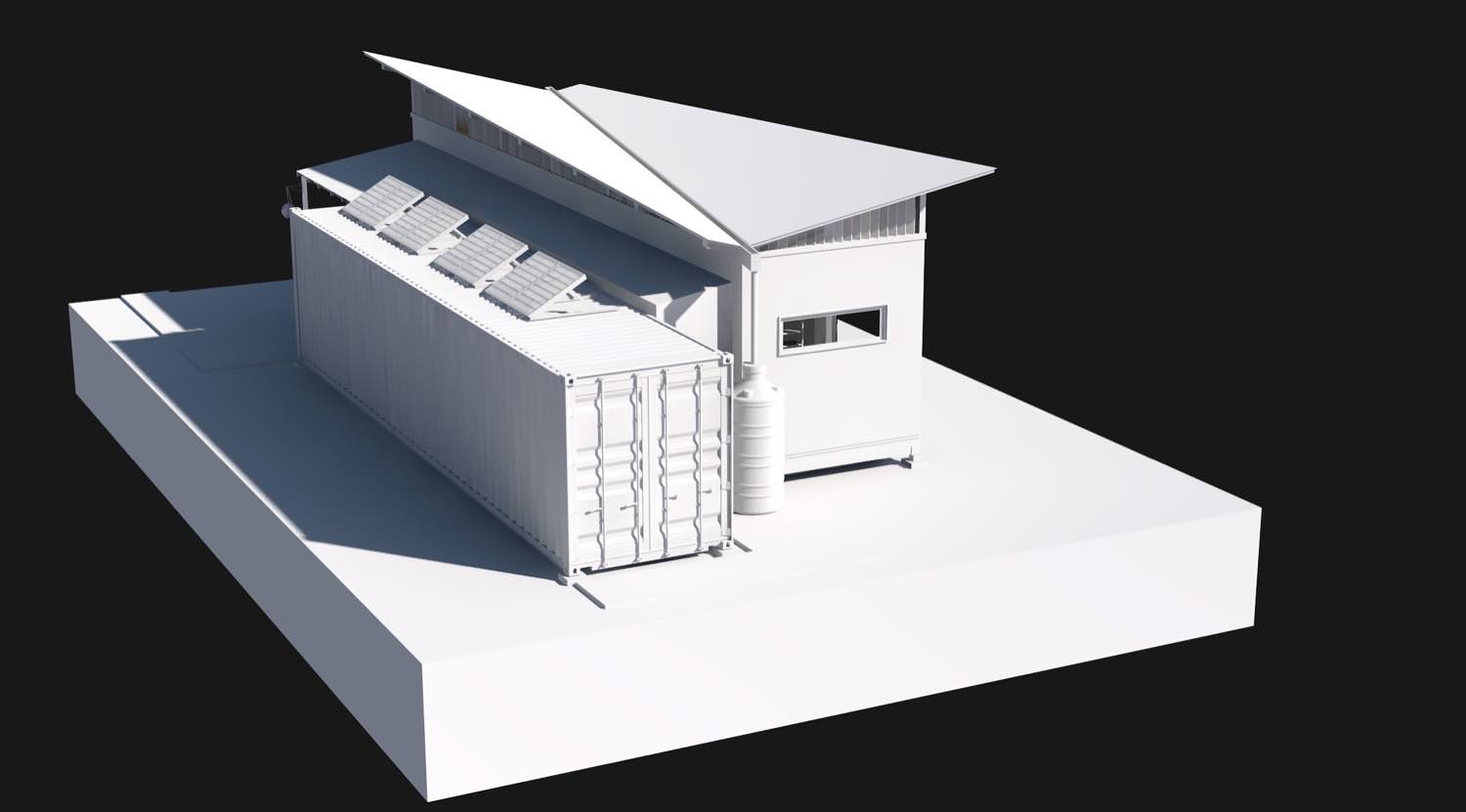

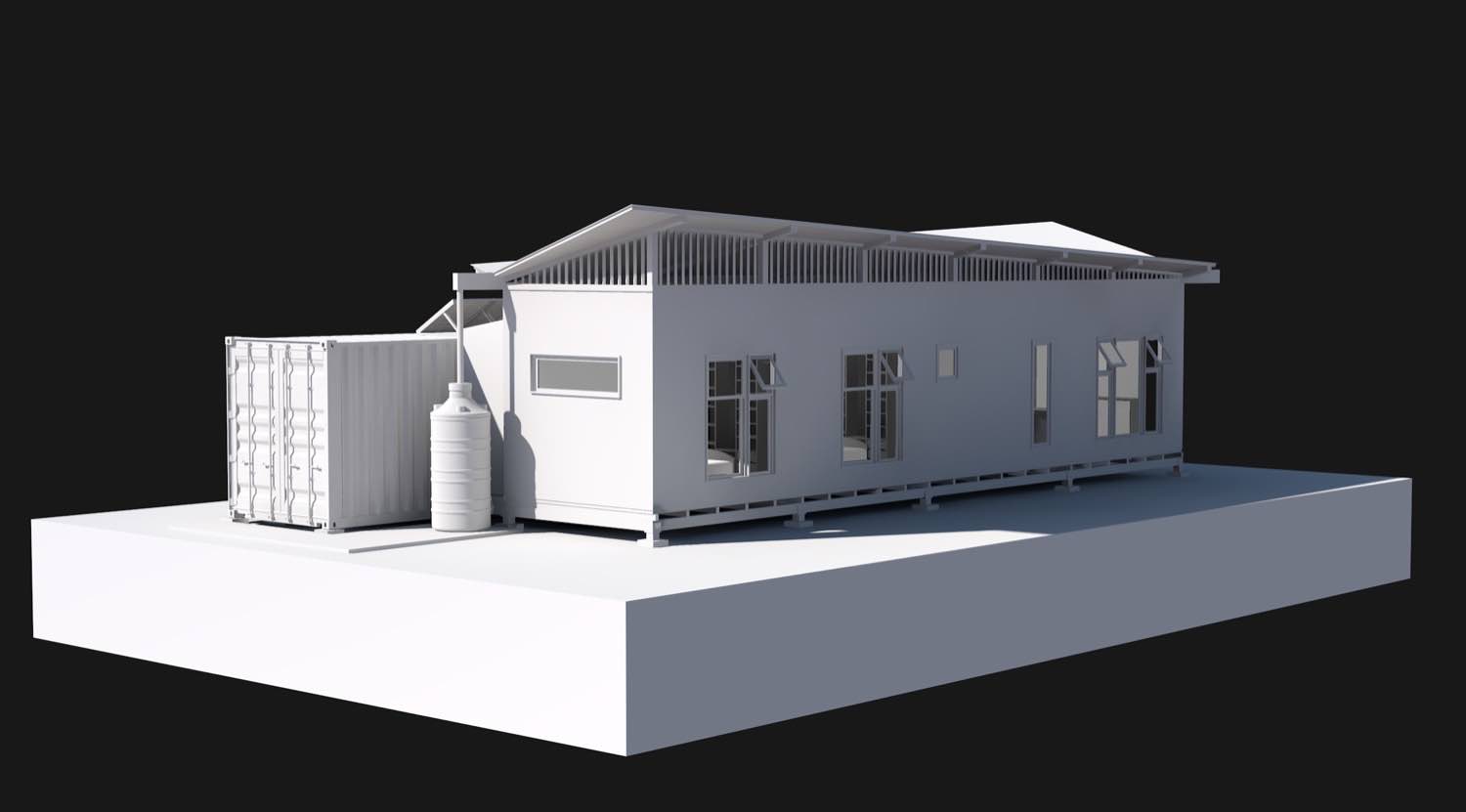

GHF Flat Pack 2 represents our continued exploration of efficient, site-assembled architecture. This guest house design refines the prefabrication strategies we developed in the first iteration, improving both the construction sequence and the spatial experience. The goal remains the same: create a building that can be fabricated off-site, transported in sections, and assembled quickly with minimal site disruption.

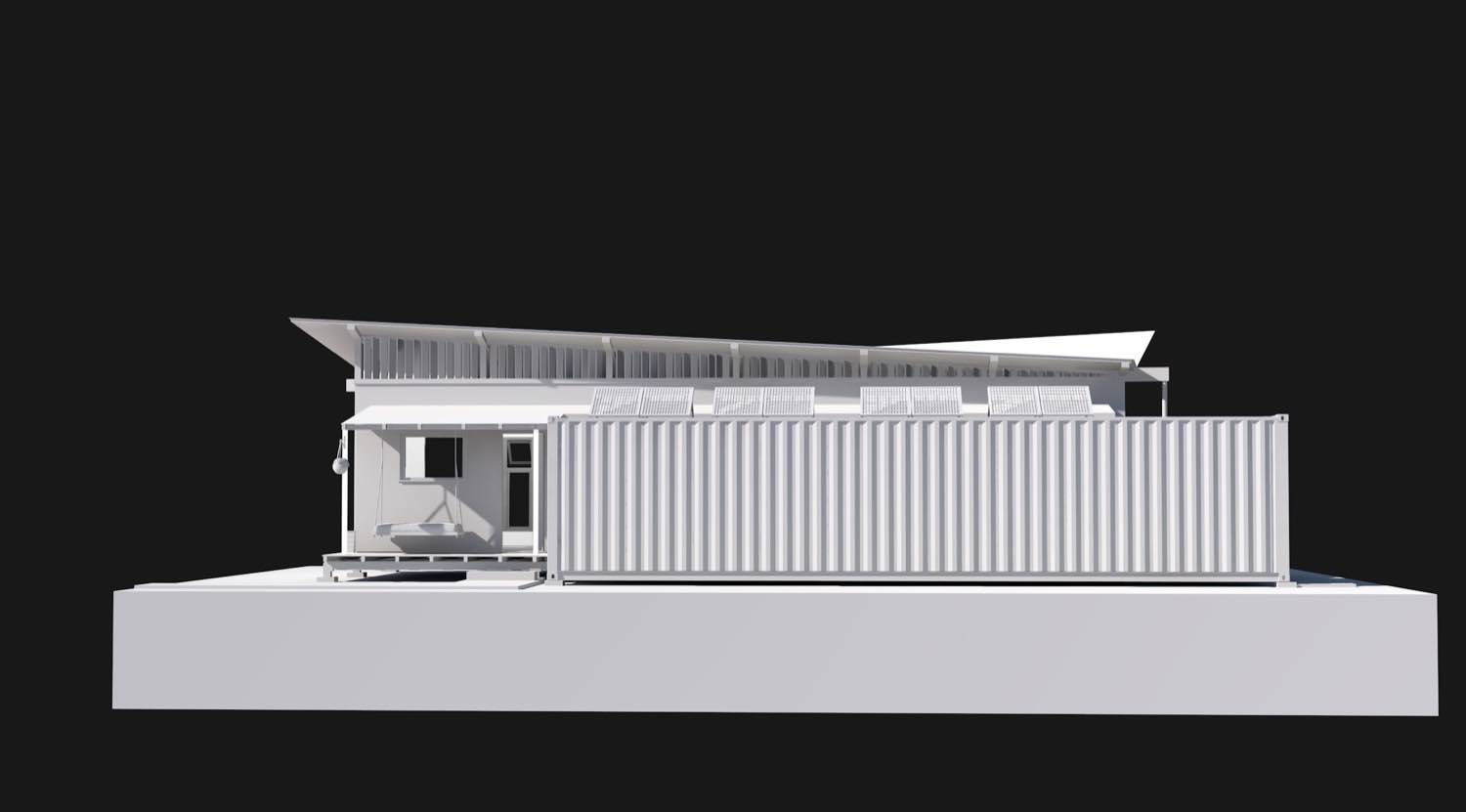

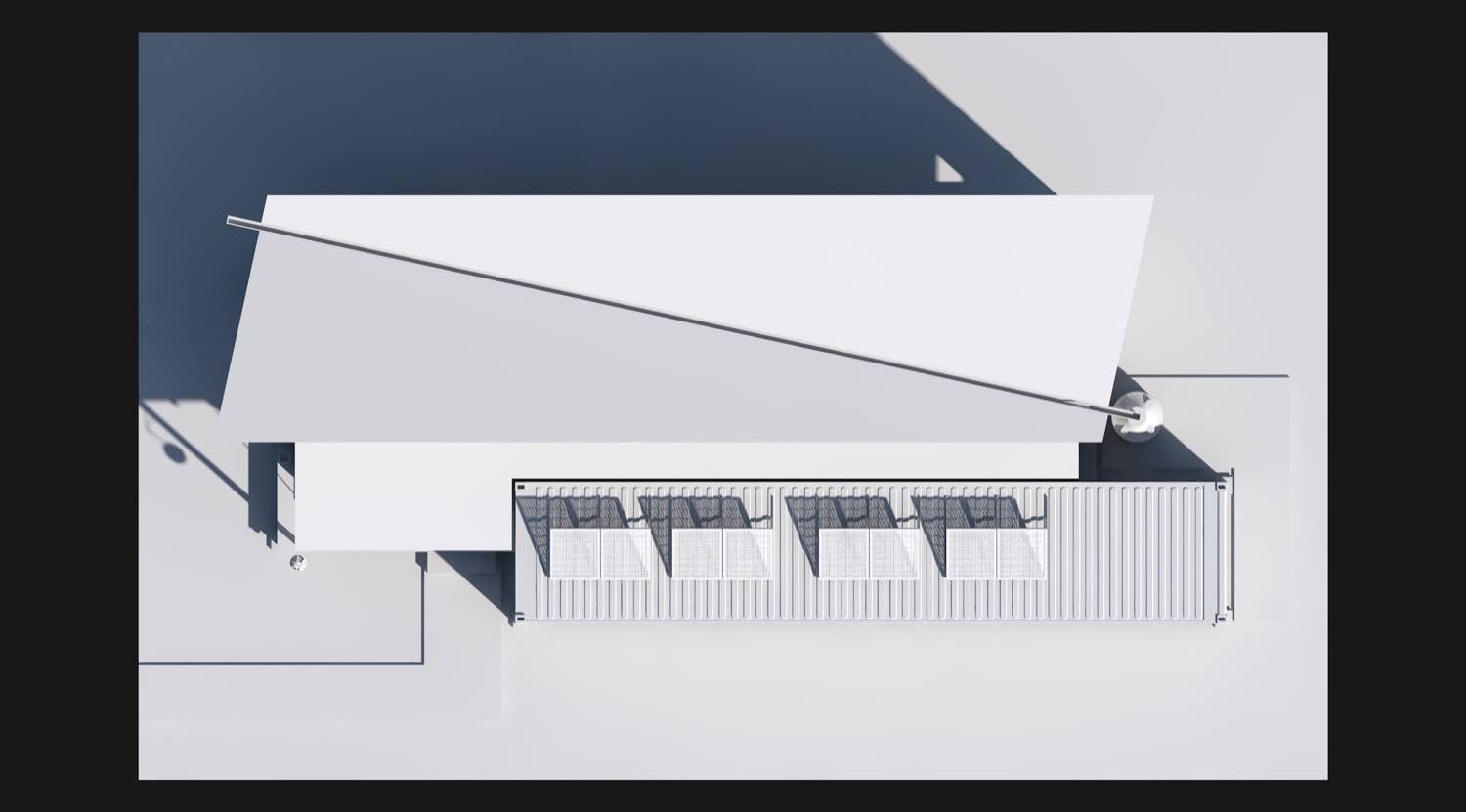

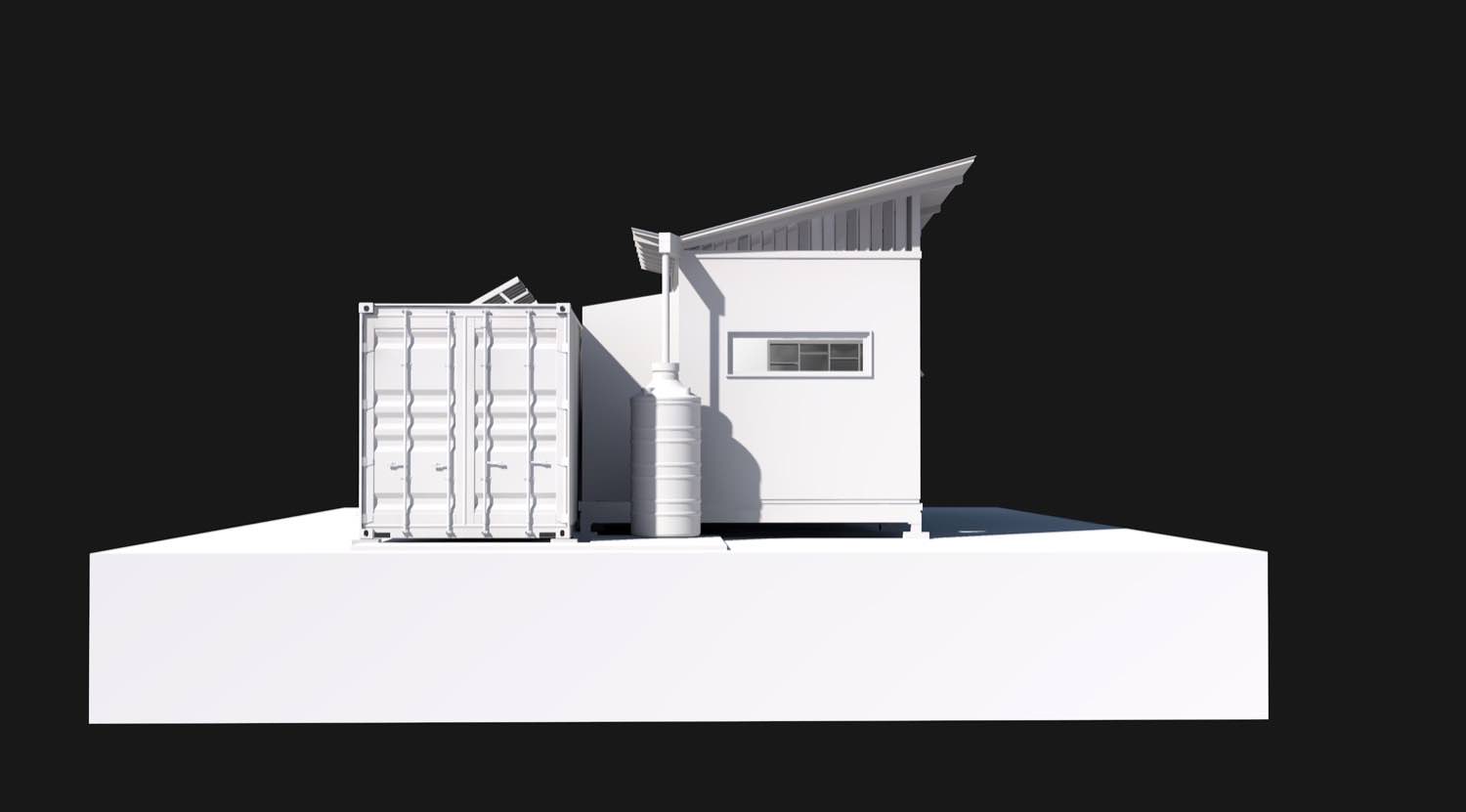

The structure consists of panelized wall and roof sections that arrive on-site ready for assembly. Each panel is built to precise tolerances in a controlled environment, then transported flat-packed to reduce shipping costs and logistics complexity. Once delivered, the panels connect through a system of integrated fasteners that allows rapid assembly without specialized equipment. This approach compresses the construction timeline from months to weeks while maintaining high quality standards.

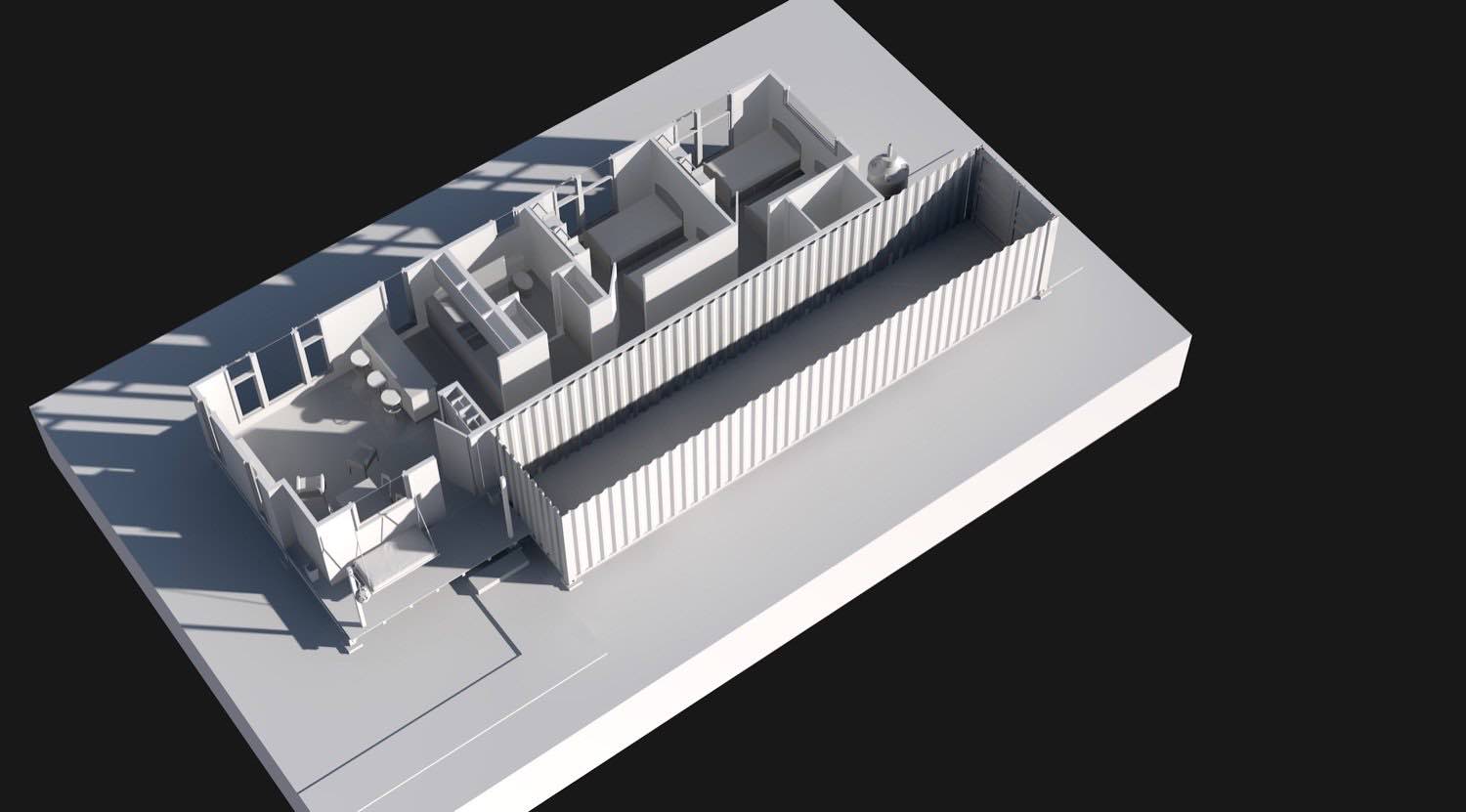

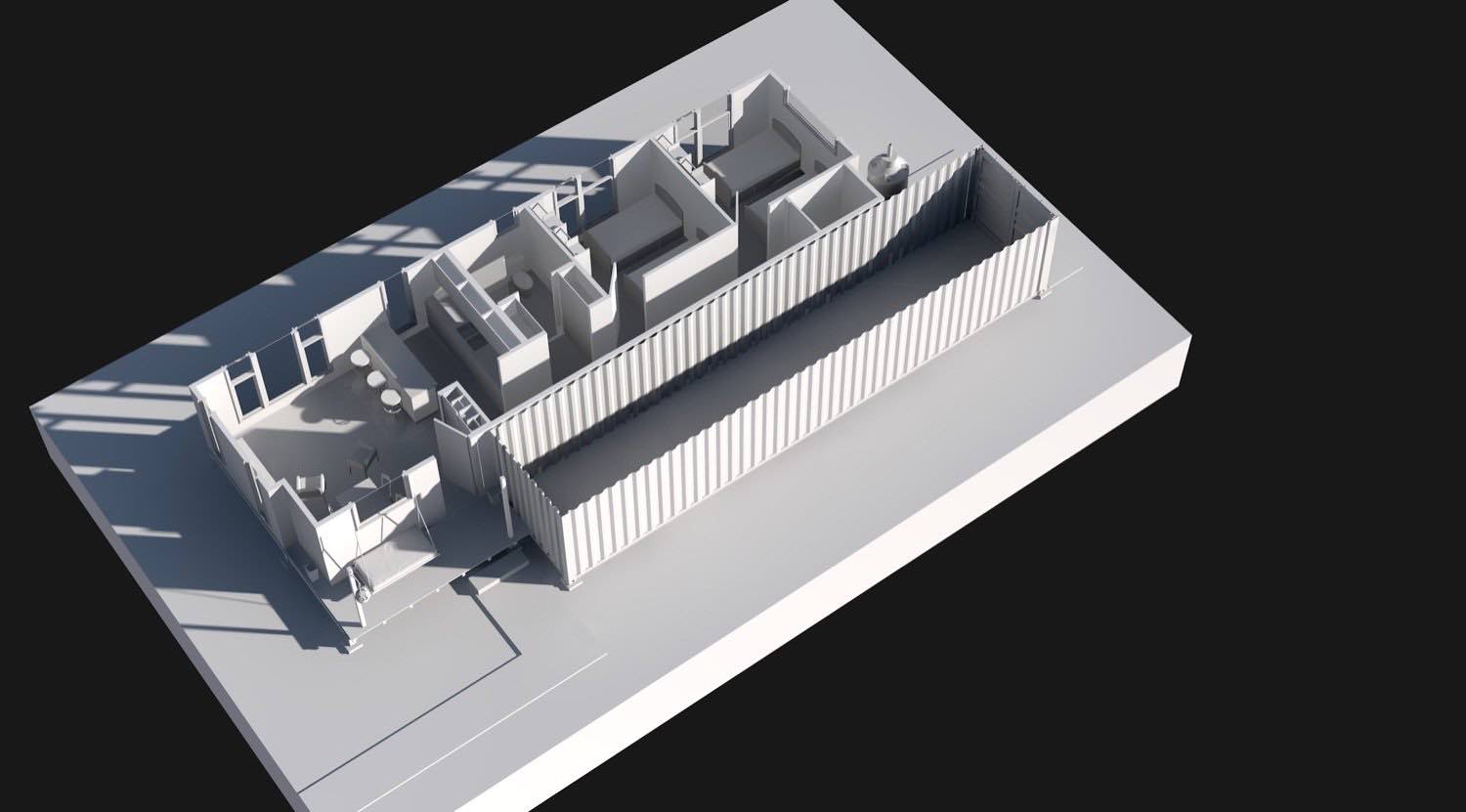

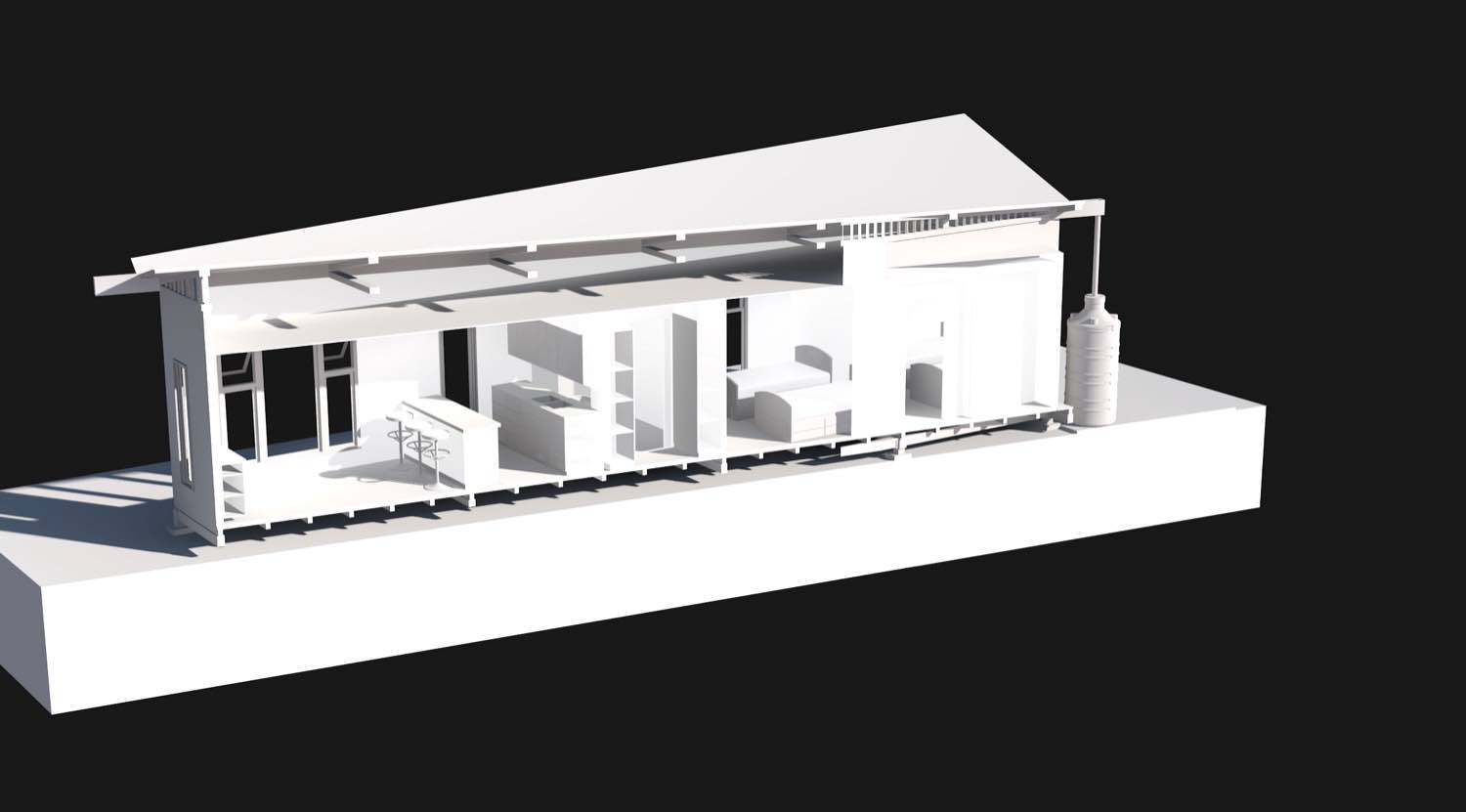

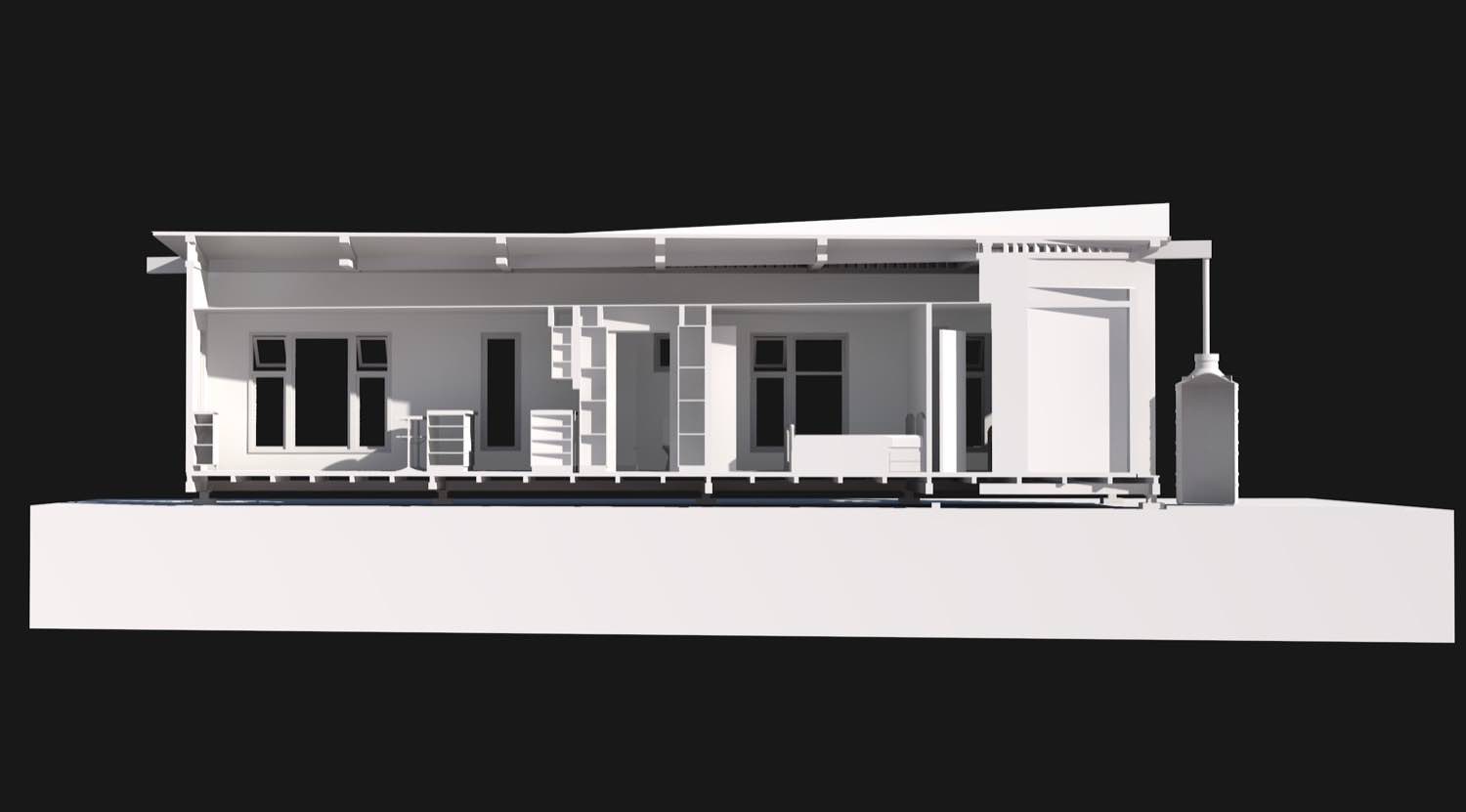

The floor plan prioritizes efficiency without sacrificing livability. A single open volume contains living, sleeping, and kitchen functions, with a separate bathroom compartment providing privacy. Large windows on multiple walls create cross-ventilation and bring natural light deep into the space. The compact footprint makes the building easier to site on constrained lots while reducing material use and energy consumption.

The exterior cladding uses simple materials that weather well and require minimal maintenance. We detailed the connections between panels to create clean lines that don't advertise the building's prefabricated origins. The roof form is uncomplicated, shedding water and snow effectively while keeping the structural system straightforward. This simplicity serves both aesthetic and practical purposes, reducing the number of custom components and potential leak points.

Inside, the space feels larger than its footprint suggests. The ceiling height varies to define different zones without walls, creating separation between living and sleeping areas through spatial volume rather than physical barriers. Built-in furniture maximizes usable space, and we've coordinated storage into the wall panels themselves. Every element serves multiple purposes, which is essential when working within a compact envelope.

The improvements in this second version address issues we identified during the first iteration. We refined the panel joints to improve thermal performance and simplified the assembly sequence based on feedback from the installation team. The window placement is more strategic, balancing views and privacy while optimizing passive solar gain. These changes make the building perform better and reduce the likelihood of installation errors.

The foundation system works with various site conditions. A simple pier foundation minimizes site disturbance and allows the building to step with sloped terrain without extensive grading. This flexibility means the design can adapt to different sites without major modifications. The building can be relocated if needed, which adds long-term value and reduces waste if circumstances change.

Prefabrication offers genuine advantages for certain projects, particularly those in remote locations or situations where time constraints matter. The quality control of shop fabrication eliminates many on-site variables, and the reduced construction timeline minimizes weather exposure during the build. For clients considering a guest house, studio, or accessory dwelling unit, this approach delivers a well-built structure more quickly than traditional stick-frame construction.

If you're exploring prefabricated options or considering an accessory structure for your property, we'd be interested in discussing how these flat pack strategies might work for your site and program.